Safety

Committed to a Culture Where We Don’t Just Follow Safety Standards, We Set Them

Safety is not just a priority. It is an integral part of who we are.

We believe safety goes beyond simply following procedures; it’s embedded in our culture and values. Our commitment to safety stems from our responsibility to protect our employees, subcontractors, and clients.

Safety is Non-Negotiable

Capital improvement and major construction projects often need to happen while other activities are ongoing in buildings or on campuses. At Energy Systems Group, we recognize the importance of maintaining safety while ensuring that operations continue smoothly. Our approach to safety is proactive and comprehensive, designed to protect your people, keep your operations running, and ensure your project stays on schedule.

Achieving OSHA VPP Star Certification

Our safety management program is adaptable by design to comply with OSHA requirements. We’ve proven this at multiple U.S. Army installations, including Fort Detrick in Frederick, Maryland, and Picatinny Arsenal in New Jersey, where our teams have demonstrated outstanding safety performance. We earned the prestigious OSHA Voluntary Protection Program (VPP) Star certification, an honor reserved for companies that show exemplary achievement in preventing and controlling occupational safety and health hazards while developing, implementing, and continuously improving their safety and health management systems.

- Subcontractor Selection: We thoroughly vet potential subcontractors to ensure they have a strong safety record.

- Hazard Identification: Before construction begins, we conduct detailed hazard assessments to identify potential risks and address them proactively.

- Tailored Safety Plans: Every project receives a customized safety plan that reflects your specific needs, goals, and site conditions.

- Safety Training and Briefings: We provide project-specific safety orientation, daily safety briefings, and pre-task planning to all workers on every project.

- Stop Work Authority: We empower all workers with the authority to stop work immediately if they perceive an imminent danger.

- Safety Stand Downs: We conduct sitewide safety stand downs focused on specific safety topics to reinforce important safety practices.

A Demonstrated Record of Safety

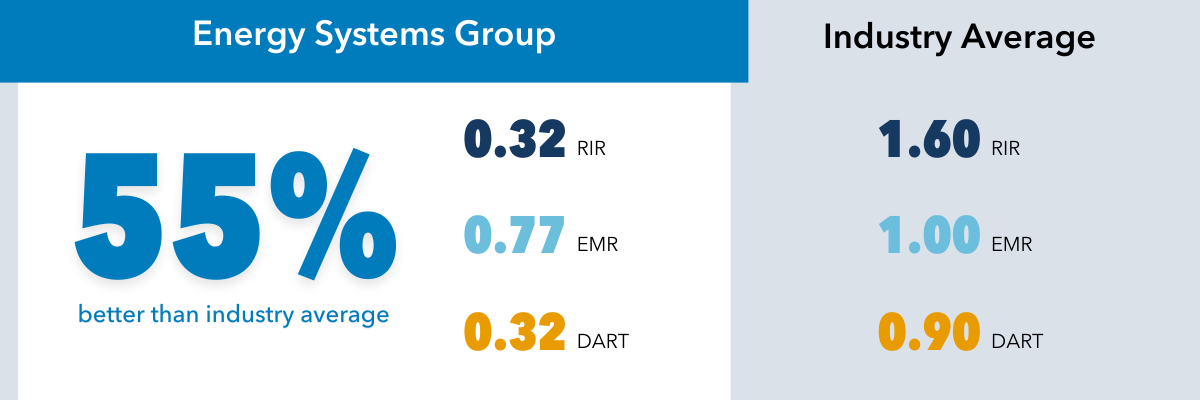

To understand the success of our safety program, we measure safety using key metrics that show how we compare to others in our industry. Our Experience Modification Rate (EMR), Recordable Incident Rate (RIR), and Days Away, Restricted, or Transferred (DART) are all consistently lower than industry averages—indicating fewer incidents, safer work environments, and strong safety practices. Below highlights how our performance stands out across each of these categories.