Safety at Energy Systems Group: Our Unwavering Commitment

Safety at Energy Systems Group: Our Unwavering Commitment

We believe safety is the foundation of success. With the proper precautions and practices in place, our employees and subcontractors can focus on what matters most, and clients can rest easy knowing their project is in safe hands. Safety is a core value of who we are and an embodiment of our culture.

OSHA VPP Star Certification

We are proud to announce that in May, we received word of our renewal for OSHA VPP Star Award status at Fort Detrick. OSHA states, "The Voluntary Protection Programs (VPP) recognize employers and workers in the private industry and federal agencies who have implemented effective safety and health management systems and maintain injury and illness rates below national Bureau of Labor Statistics averages for their respective industries."

We have been grateful recipients of this award since 2010. This recognition is a testament to our strenuous safety practices and precautions. As OSHA reports, "To participate, employers must submit an application to OSHA and undergo a rigorous on-site evaluation by a team of safety and health professionals." We are so proud of our Fort Detrick team for delivering safety excellence!

Safeguarding Projects

As a partner for major construction projects, we understand that many of our projects take place alongside public figures, such as teachers educating future generations or county managers working to better their communities. We take this responsibility seriously and work with you to provide minimal disruptions to your busy workday. Our stringent safety measures protect everyone involved, maintain operational continuity, and keep projects on track. Our following safety practices and procedures are in place to ensure safety is the forefront during any project.

Proven Safety Practices and Procedures

- Subcontractor Selection: Rigorous vetting to ensure a strong safety track record.

- Pre-Construction Hazard Reports: Identifying and addressing potential issues before work begins.

- Custom Safety Plans: Tailored to each project's specific needs and goals.

- Comprehensive Safety Training: Project-specific orientation, daily briefings, and pre-task planning.

- Empowered Workforce: Authority to issue stop-work notices if imminent danger is perceived.

- Safety Stand Downs: Regular focus on critical safety topics.

Leading Safety Performance

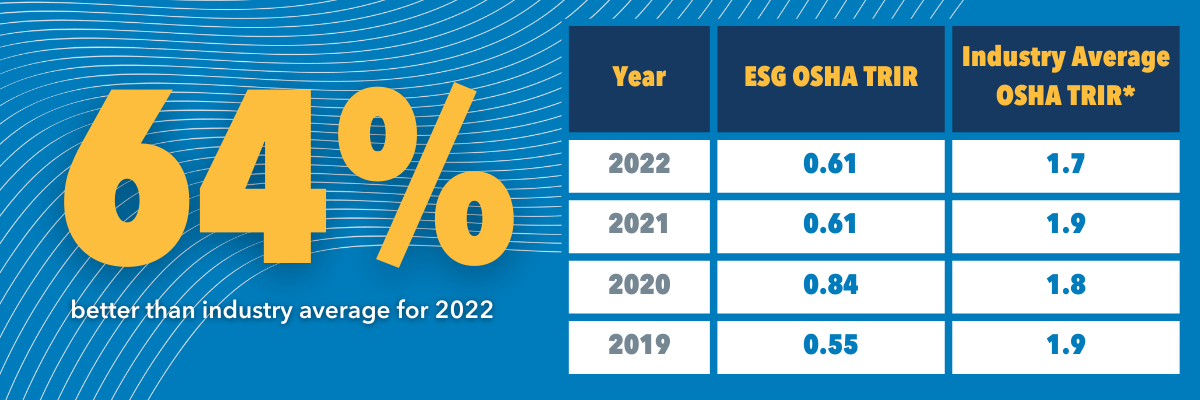

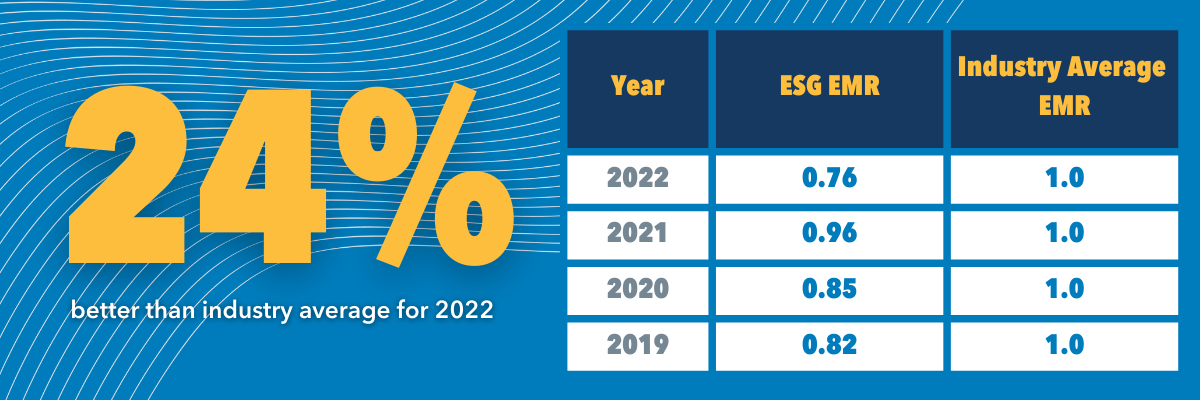

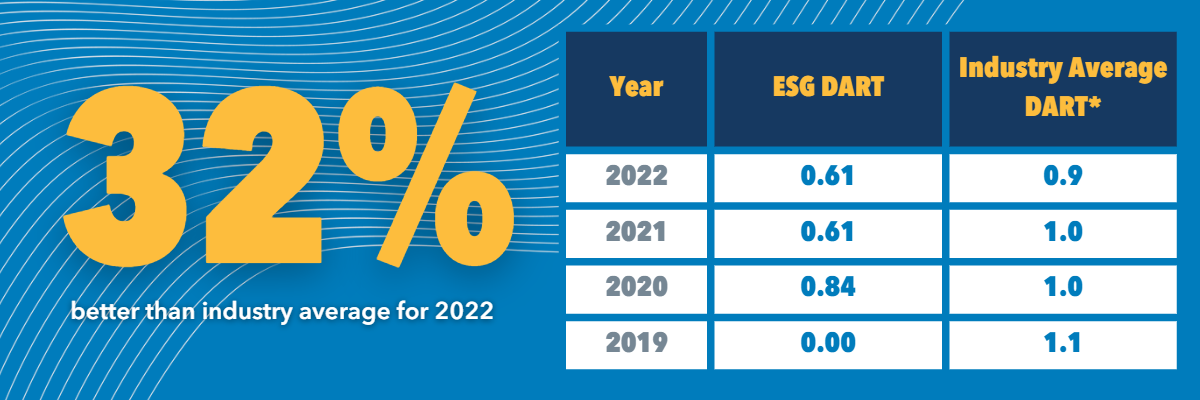

Don’t take our word for it. Our safety stats, from our Experience Modification Rate (EMR) to our Total Recordable Incident Rate (TRIR) to Days Away Restricted Time (DART), speak for themselves. Take a look at our stats versus the industry average.

Total Recordable Incident Rate (TRIR) measures the number of work-related injuries and illnesses that occur per 100 full-time employees in a year. A lower rate indicates fewer injuries/illnesses per employees.

*U.S. Bureau of Labor Statistics–North American Industry Classification System (NAICS) Code–236220 (Commercial and Institutional Building Construction)

Experience Modification Rate (EMR) is based on a company's history of workplace safety and claims management compared to similar-sized companies in the same industry. A lower rating indicates that the company has a lower risk of claims, so workers' compensation premiums will be lower.

Days Away Restricted Time (DART) calculates the number of recordable workplace injuries or illnesses that result in days away from work, restricted work activity, or job transfer divided by the total hours worked by all employees. The lower the number, the better.

*U.S. Bureau of Labor Statistics–North American Industry Classification System (NAICS) Code–236220 (Commercial and Institutional Building Construction)

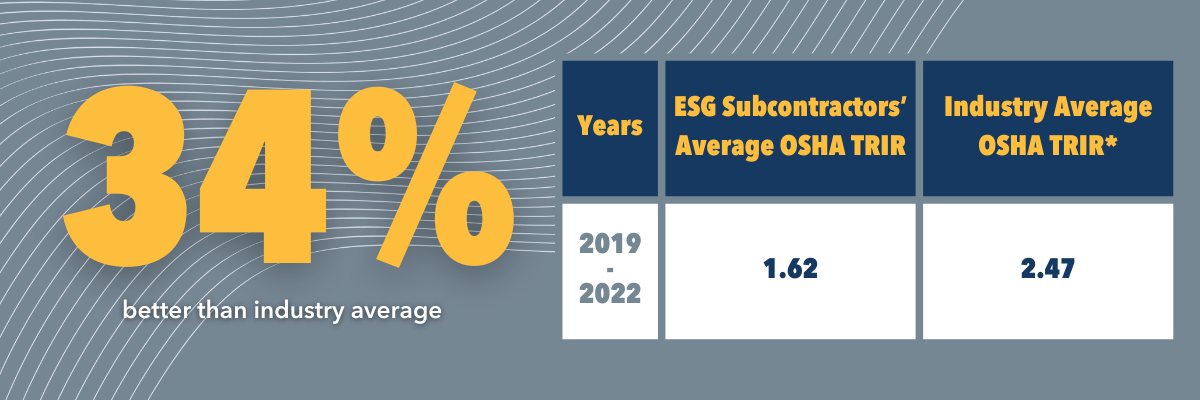

Exceeding Subcontractor Safety

Our subcontractor safety metric reports highlight our better-than-industry-standard safety performance. To illustrate this, the table below shows that ESG’s 2020–2022 hired subcontractors’ average TRIRs and EMRs were below industry averages.

Total Recordable Incident Rate (TRIR) measures the number of work-related injuries and illnesses that occur per 100 full-time employees in a year. A lower rating indicates fewer injuries/illnesses per our subcontracting teams.

*U.S. Bureau of Labor Statistics–North American Industry Classification System (NAICS) Code–236220 (Commercial and Institutional Building Construction)

Experience Modification Rate (EMR) is based on a company's history of workplace safety and claims management compared to similar-sized companies in the same industry. A lower rating indicates that the company has a lower risk of claims, so workers' compensation premiums will be lower.

Our Commitment to Safety

Our company-wide safety program reminds employees of our values no matter the task at hand. Our S.A.F.E. One program stands for Safe Actions For Everyone and reinforces that safety is a continuous effort, relevant at all times, in every situation. The program is built on five core values that emphasize not only work safety but personal responsibility and positive outcomes both on and off the job.

- Striving to eliminate all preventable injuries and illnesses.

- Ensuring a secure, safe, and environmentally sustainable workplace.

- Demonstrating a high regard for safety and environmental stewardship.

- Providing comprehensive safety and health training.

- Measuring success through our commitment to safety and environmental stewardship.

Ready to Experience Unmatched Safety and Quality?

If you would like to learn more about how ESG can bring our safety excellence to your next project, contact us today. Let us show you how our unwavering commitment to safety can make a difference in your capital improvement projects. Together, we can build a safer, more efficient future.